| No. | Liquid | Boiling Point Temperature | Latent Heat of Vaporization 증발잠열 L=h(vapor)-h(liquid) | Density of Liquid at Boiling Point | ASHRAE NO | Enthalpy (Vapor) | Enthalpy (Liquid) | |

| (℃) | (K) | (KJ / kg) | ρ , (kg / m³) | h, (kJ/kg) | h, (kJ/kg) | |||

| 1 | LNG(CH4 Methane) | -163 | 110.15 | 510.83 | 422.4 | R50 | 510.83 | 0 |

| 2 | 프로판 (Propane) | -42.11 | 231.04 | 425.59 | 580.9 | R290 | 525.95 | 100.36 |

| 3 | 부탄 (Butane) | -0.49 | 272.66 | 385.71 | 601.3 | R600 | 584.58 | 198.87 |

| 4 | 프로필렌 ( Propylene ) | -47.69 | 225.46 | 439.16 | 609.1 | R1270 | 529.3 | 90.14 |

| 5 | 암모니아 (Ammonia ) | -33.33 | 239.82 | 1369.5 | 682 | R717 | 1418.26 | 48.76 |

| 7 | Liquid Oxygen 산소 | -183 | 90.15 | 213.06 | 1141.2 | R732 | 79.69 | -133.37 |

| 8 | 액화질소 LN2 | -195.8 | 77.35 | 199.18 | 806.1 | R728 | 77.16 | -122.02 |

| 9 | 액체이산화탄소 LCO2 Liquid carbon dioxide | -37.0 | 236.15 | 316.92 | 1101.0 | R744 | 435.9 | 118.98 |

| 10 | 아르곤 | -185.8 | 87.35 | 161.14 | 1395.4 | R740 | 43.62 | -117.52 |

| 11 | 헬륨 | -268.9 | 4.25 | 20.75 | 124.73 | R704 | 30.59 | 9.84 |

| 12 | 액화수소 (LH2) (Parahydrogen) | -252.8 | 20.35 | 443.9 | 70.8 | R702p | 189.5 | -254.4 |

| No. | Insulation Material | SI Unit | Metric | Density | PART | REMARK (ASTM No.) |

| k [W/m·℃] | k [kcal/h·m·℃] | ρ, kg/m³ | ||||

| 1 | 액화수소 Liquid Hydrogen Insulation | |||||

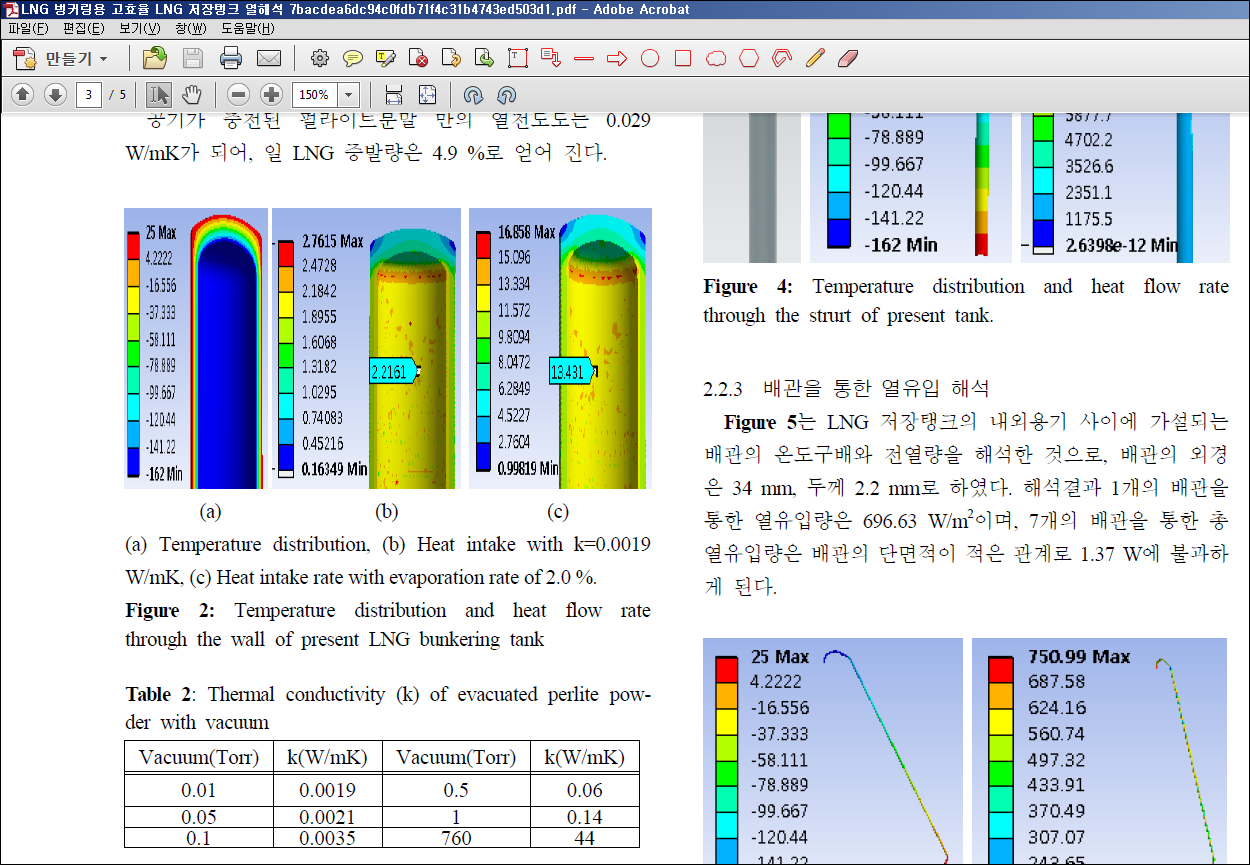

| Perlite Vacuum Pressure = 0.01 Torr | 0.0019 | 0.00163 | 65 | All Vessel | ||

| (일반적임) Perlite Vacuum Pressure = 0.05 Torr | 0.0021 | 0.00181 | 65 | All Vessel | ||

| Perlite Vacuum Pressure = 0.10 Torr | 0.0035 | 0.00301 | 65 | All Vessel | ||

| Perlite Vacuum Pressure = 0.5 Torr | 0.06 | 0.0516 | 65 | All Vessel | ||

| Perlite Vacuum Pressure = 1.0 Torr | 0.14 | 0.1204 | 65 | All Vessel | ||

| Perlite Vacuum Pressure = 760 Torr (atm) | 44.00 | 37.833 | 65 | All Vessel | ||

| MLI ; Multilayer Vacuum Insulation | ||||||

| 1 | Steel Shell Plate (C/S) | 45.29885 | 38.95 | 7850 | Shell & Roof | ??? |

| 2 | PolyUrethane Foam (PUF) | 0.026749 | 0.023 | 40 | Shell & Roof | |

| 3 | Perlite | 0.044194 | 0.038 | 65 | Shell & Roof | |

| 4 | Resilient blanket | 0.026749 | 0.023 | 17.5 | Shell & Roof | |

| 5 | Pre-stressed concrete | 2.300414 | 1.978 | - | Shell & Roof | |

| 6 | Cellular glass | 0.043031 | 0.037 | 120 | Shell & Bottom | |

| 7 | ||||||

| 8 | Perlite Concrete Block (PCB) | 0.27 | 0.2322 | 1200 | Bottom | |

| 9 | Level Concrete | 0.29075 | 0.25 | - | Bottom | |

| 2 | Cellular Glass Block | 0.037216 | 0.032 | 120 | Bottom | |

| 10 | Dry sand | 0.157 | 0.135 | - | Bottom | |

| 11 | Level concrete | 0.29075 | 0.25 | - | Bottom | |

| 12 | Fiber Glass | 0.040705 | 0.035 | 24 | Roof Deck 상단 | |

| No. | Insulation Material | SI Unit | Metric | Density | REMARK (ASTM No.) |

| h [W/m²·℃] | h [kcal/h·m²·℃] | ρ, kg/m³ | |||

| 1 | Liquid to Steel | 23.26 | 20 | - | |

| 2 | Air to Steel | 11.63 | 10 | - | |

| 3 | Air to concreate | 11.63 | 10 | - |

| 번호 | 구분 | h[kcal/h·m·℃] | |

| 1 | 공기 가열, 냉각 | 1~50 | |

| 2 | 물 가열, 냉각 | 200~15000 | |

| 3 | 기름 가열, 냉각 | 50~1500 | |

| 4 | 수증기 과열 | 20~100 | |

| 5 | 수증기 막상 응축 | 4000~15000 | |

| 6 | 수증기 방울상 응축 | 50000~100000 | |

| 7 | 유기 증기 응축 | 1000~2000 | |

| 8 | 물 끓음 | 1500~40000 | |

Insulation System of PUF SPRAY type applicable to LPG/LEG/LNG liquidified cargi tank

Applicable to DECK TANK due to high environmental effect resistance

Construction is easy, and easy maintenance and repair

Relatively short construction period saves costs

| Properties | Unit | Allowance | Test Method |

| Sprayed density | kg/m³ | 36 – 50 | ASTM D1622 |

| Compressive strength | kg/cm² | ≥ 1.7 | ASTM D1621 |

| Tensile strength | kg/cm² | ≥ 2.0 | ISO 1926:2009 |

| Thermal conductivity at 20°C | W/mK | ≤ 0.021 | ASTM C518 |

| at 20°C aged 4 month | W/mK | ≤ 0.023 | ASTM C518 |

| Dimensional stability | vol% | ≤ 1 | ASTM 2126 |

| Closed cell content | % | ≥ 90 | ASTM D6226 |

| Water absorption | g/100cm² | ≤ 3.0 | KS M 3809 |

| Flammability | – | B2 | DIN 4102, Part 1 |

| Properties | Unit | Allowance | Test Method |

| Sprayed density | kg/m³ | 50 – 56 | ASTM D1622 |

| Compressive strength | kg/cm² | ≥ 2.5 | ASTM D1621 |

| Tensile strength | kg/cm² | ≥ 2.8 | ISO 1926:2009 |

| Thermal conductivity at 20°C | W/mK | ≤ 0.022 | ASTM C518 |

| at 20°C aged 4 month | W/mK | ≤ 0.023 | ASTM C518 |

| Dimensional stability | vol% | ≤ 1 | ASTM 2126 |

| Closed cell content | % | ≥ 90 | ASTM D6226 |

| Water absorption | g/100cm² | ≤ 4.0 | KS M 3809 |

| Flammability | – | B2 | DIN 4102, Part 1 |

// CANVAS 이미지 그리기 예제 https://itrooms.tistory.com/213 // 로칼스토리지 사용 방법 https://www.daleseo.com/js-web-storage/이 파일의 총 크기는 [] 입니다.